Lightweight Filling Material Expandable Graphite Foam EPS

Lightweight Filling Material Expandable Graphite Foam EPS

Good fire resistant capability, low thermal conductivity, low energy consumption; they are mainly applicable to higher-level thermal insulation materials of buildings.

Advantages of graphite eps:

1. First class production process worldwide

2. Intelligent DCS

3. Advanced equipments

4. Superior human resorces

5. Quality assurance: ERP and ISO9002

Specifications of graphite eps:

|

Classification |

Spec. |

Diam Range (mm) |

Times |

Density |

Blowing Agent(%) |

Residual SM(ppm) |

Moisture (%) |

Coating Agent (ppm) |

Oxygen Index(%) |

|

Graphite grade |

HF-301 |

1.00~1.60 |

55~70 |

14~18 |

5.5~6.8 |

≤2000 |

≤2.0% |

≤3200 |

≥30 |

|

HF-302 |

0.85~1.25 |

50~60 |

16~20 |

||||||

|

HF-303 |

0.70~0.90 |

40~55 |

18~25 |

||||||

|

HF-401 |

0.50~0.80 |

35~45 |

22~30 |

||||||

|

HF-501 |

0.40~0.60 |

30~40 |

25~35 |

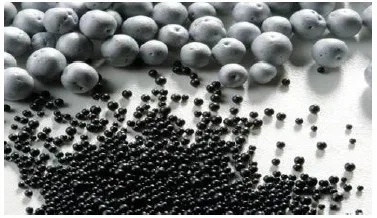

Photos of graphite eps:

Applications of graphite eps:

Graphite (SEPS) polystyrene board, called the adiabatic with polystyrene foamed plastic board, graphite mold is a new kind of polystyrene insulation board. Its production process is in polystyrene (EPS) added 5% 50% quality of expanded graphite and 2% - 20% of phosphoric acid compounds as flame retardant, the preparation of expansion by using the method of suspension polymerization PS particles. In polystyrene (EPS) import graphite, make it on the basis of keeping excellent insulation performance, has more excellent flame retardant properties

Graphite of polystyrene has solved the key problem of flame retardant: the introduction of high melting point of graphite, improve the melting temperature of styrene and extend the melting time of styrene; Under the same conditions, SEPS plate partial melting, melting time of 50 s; And EPS plate almost all melting, melting time was 14 s; Nearly fire baking, SEPS halogen-light, and ordinary EPS has instantaneous flame, the flame spread easily. In addition, SEPS plate has better electric conductivity, also conducive to production of anti-static fire.

Graphite of polystyrene compared with ordinary polystyrene board, has two advantages: low coefficient of thermal conductivity and low density. SEPS plate thermal conductivity is 0.032 w/m.k, average coefficient of thermal conductivity of EPS board is 0.041 w/m.k; The density of graphite of polystyrene was also significantly lower than normal polystyrene board, under the same heat preservation effect, means the use of raw materials can be greatly reduced.

Expandable polystyrene(EPS) is packed in an outer polypropylene woven bag or kraft-plastics laminated bag with an inner modified PE/PA film bag. Each bag has the net weight of 25kg. It can be also packed in bulk bags of over 500kg net.

Packing Weight: 25kg/750kg/850kg

We can also accept customized packaging way.

Product Tag

| 3d eps steel mesh wall panel wood |

| 3d eps steel mesh wall panel assembly |

| 3d eps steel mesh wall panel board |

| 3d eps steel mesh wall panel brick |

| 3d eps steel mesh wall panel cover |

| 3d eps steel mesh wall panel decor |

| 3d eps steel mesh wall panel enclosure |