F-301 Flame Retardant Raw Material For Eps Block

Update::2023-02-21 16:28 View:

Description:

FIRE RETARDANT GRADE F-301

| SPECIFICATION | BEADS SIZE | FOAM MULTIPLE |

FOAM DENSITY G/L |

EQUAL TO OTHER BRAND | |

| LOYAL | XINDA | ||||

| F-301 | 1.00-1.60 | 70-85 | 12.0-14.0 | FMS | ZKF301 |

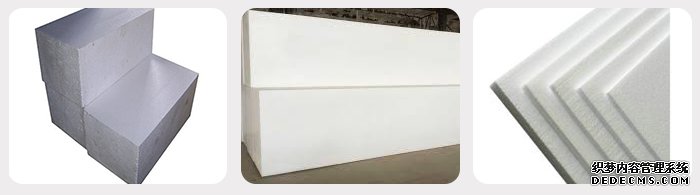

The applicable temperature range is wide when processing and molding. Good strength. Manufacturing costs are low. Less steam consumption and energy saving. It is suitable for all kinds of packaging boxes and large board forming (especially the packaging of light electronic products).

Molding Method:

Processing should go through the following three steps: pre-foaming, storage and molding.

Pre-foaming

Heating the steam expands the particles by a factor of about 50-90 in volume, either in batch or continuous operations. The expansion rate of the beads is related to the type of pre-foaming equipment used, steam and heating time and other factors. Therefore, if the beads are to be foamed to a certain extent, the most appropriate conditions must be found through experiments. (Vapor pressure 0.2~1.0kg/cm2).

Save

The pre-expanded beads should be stored at room temperature for about 24 hours (at least 6 hours), during which the excess water inside and outside the foamed beads has evaporated, and air has penetrated into the pre-expanded beads. within the voids, which will facilitate subsequent processing.

Molding

The stored pre-foamed beads can be formed by manual, semi-automatic or fully automatic forming machines. When molding, low-pressure steam is first introduced to blow away the air between the beads, and then the steam pressure is gradually increased to 0.5 ~ 1.0kg/cm2, so that the pre-expanded beads are formed in the mold, and finally water or vacuum pumping, After cooling, the molded product is taken out.

Product Tag

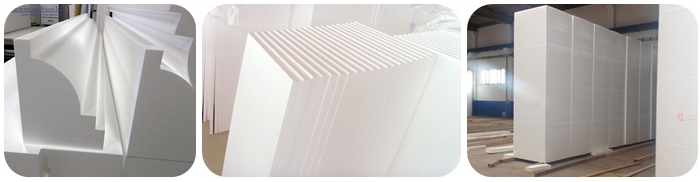

| eps cornice moulding |

| eps cornice production line |

| eps foam cornice |

| eps foam cornice machine |

| eps foam application |

| eps foam board |

| eps foam blocks |

| eps foam core |

| eps foam density |

| eps foam exterior insulation |

| eps foam extrusion machine |